LNG CCS

We

specialize in producing and supplying all nonferrous parts used for

extremely low temperature cargo containment system of LNGC as

main means of transportation in the Eco-friendly energy transition era.

extremely low temperature cargo containment system of LNGC as

main means of transportation in the Eco-friendly energy transition era.

Ship Building

LNG CCS

Metal Solution

Metal Solution

For LNGC, two types of cargo containment system are mainly produced : MarkⅢ and NO96. SAMWOO MCP manufactures key parts of the cargo containment system of both models in state-of-the-art facilities and secure an exclusive position as a reliable partner through perfect quality control system.

We have been participating in the research and development stage for additional types under development and are actively participating in efforts to preoccupy the market and expand the market.

Moreover, in the industry where low carbon and eco-friendliness are emphasized, we are constantly striving for research and development to efficiently reduce costs and improve competitiveness.

Product & Solution

- MARKIII

- NO96

- NO96 SUPER+

- NEXT1

01.

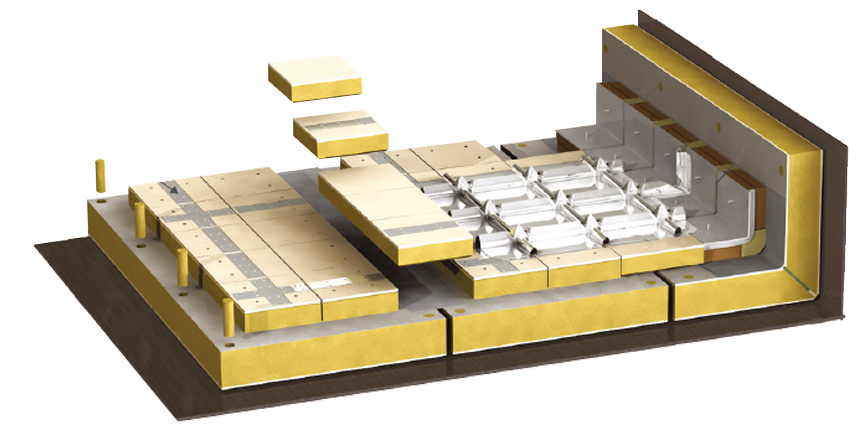

MARKIII

MARKIII

The Mark III membrane system is a containment and insulation

system, directly supported by the vessel’s hull structure. It is composed of a

primary corrugated stainless steel membrane, positioned on top of prefabricated

insulation panels, including a complete secondary membrane made of composite

material. This modular system employs standard

prefabricated components that can accommodate any shapes and capacities of tanks.

They are designed for mass production techniques and easy assembly.

02.

NO96 TYPE

NO96 TYPE

The primary and secondary membranes are made of Invar, a 36% nickel-steel alloy, 0.7mm

thick. The primary membrane contains the LNG cargo, while the secondary membrane,

identical to the primary, ensures a 100% redundancy in case of leakage. Each of the

500mm wide Invar strakes is continuously spread along the tank walls and is evenly

supported by the primary and the secondary insulation layers.

With the approval of GTT, SAMWOO MCP manufactures and supplies all metal joint

parts (e.g., coupler) for a cargo containment system.

03.

NO96 SUPER+ TYPE

NO96 SUPER+ TYPE

In the case of the newly developed NO96 Super+ type of GTT, SAMWOO MCP joined the

research and development project at the beginning and contributed to determining product

specifications.

04.

NEXT1 type

NEXT1 type

The NEXT 1 membrane system, a new type of LNGC CCS under

development, is made up of a fully redundant membrane and insulating system,

directly supported by the ship’s inner hull. It includes two independent metallic

membranes, both supported by a layer of insulating material.

The primary barrier, directly in contact with the cargo, is a corrugated

stainless steel membrane, adapted from GTT’s Mark technologies, whereas the

secondary barrier, achieving full redundancy of the tightness function, is a Fe-36%

Ni alloy membrane. With the approval of GTT, SAMWOO MCP will manufacture and supply

all metal joint parts for a cargo containment system.

Mark III Specification

| Specification | MarkⅢ | MarkⅢ Flex | MarkⅢ Flex+ |

|---|---|---|---|

| Boil-off Rate (BOR)* (170K m³ vessel) |

From 0.15 to 0.125% | From 0.10 to 0.085% | 0.07% |

| Date to market | 1969 (Mark I concept) | 2011 | 2017 |

| Insulation | Foam 130kg / m³ | ||

| Membranes |

Primary : Stainless steel 304L - 1.2 mm Secondary : composite material |

||

| Support | Primary and secondary panel : foam and plywood | ||

| Thickness Primary + Secondary panel |

270 mm = 100 + 170 | 400 mm = 100 + 300 | 480 mm = 100 + 380 |

* BOR is project dependent due to vessel size, tank arrangement and reinforcements.

NO96 Specification

| Specification | NO96 Perlite | NO96 GW | NO96 L03 | NO96 L03+ |

|---|---|---|---|---|

| BOR* (170K m³ vessel) |

0.15% | 0.125% | 0.11% | 0.10% |

| Main insulating material | Perlite | Glass-wool | Glass-wool and foam 130kg/m³ | |

| Membranes | Invar® 0.7 mm | |||

| Support | Boxes with bulkheads : plywood |

Boxes primary and top secondary with bulkheads : plywood Panels lower secondary : foam & plywood |

Boxes with bulkheads : plywood Panels : foam & plywood |

|

| Thickness | 530 mm (primary box : 230 mm + secondary box : 300 mm) | |||

* BOR is project dependent due to vessel size, tank arrangement and reinforcements.